Sections

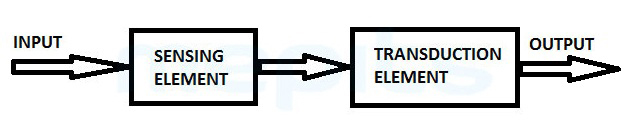

Transducer can be considered as a device converting one form of energy to another form. Electrical transducers can be considered as a device meant to convert a form of energy to equivalent electrical signals. The physical quantity to be measured can be position, displacement, flow, temperature, strain, velocity etc. and the output is in the form of electrical parameters like current, capacitance, voltage, inductance, change in resistance etc. Transducer block diagram is given below.

Transducer consists of two main parts, that is,

Transducers are of different types and classified based on different criteria as:

Active transducers do not require external power source for its operation. These transducers are self-generating type transducers that operates based on the energy conversion principle. Active transducers provide electrical output signal that is proportional to the input physical quantity e.g. thermocouple. Thermocouple produces a voltage depending on the measured voltage and known voltage and when there is a difference in voltage, electricity is produced.

Passive transducers are the ones that require external power source for their working and are thus not self-generating transducers. External power source can be audio frequency generator or DC power supply. When physical quantity is measured using these transducers the output signal obtained is in the form of variations in capacitance, resistance, inductance etc. which must be converted further to equivalent current or voltage. Photocell or LDR is an example of passive transducer which outputs a variation in resistance when light rays falls on it. This resistance change is transformed to proportional electrical signal with the use of bridge circuit. Thus intensity of light is measured by photocell.

Bonded strain gauge is also an example of passive transducer which is used for the measurement of pressure or strain. As the pressure is applied on the strain gauge decreases or increases then the stain gauge compresses or bends thereby causing resistance of the wire that is bonded on it to decrease or increase. Bridge helps in measuring equivalent change in stress with the change in resistance.

Transducers are of different types depending on the physical quantity being measured, that is, displacement transducers which measure displacements and convert it to electrical signal, pressure transducers which measure pressure and there is temperature transducer which measures temperature and converts it to another quantity such as electric voltage, mechanical movement or pressure. Temperature transducer signals can be processed by controllers and given out to actuators which can be used for controlling heat of a system. Temperature transducers find its use in process industries like food processing, pharmaceuticals etc. where temperature controlling is important during manufacturing.

Temperature transducers that are commonly used nowadays are

Thermocouple is an electrical device that is one of the common, versatile and convenient devices which responds to temperature difference and produces an electric current. Thermocouple is popular as it is simple, rugged, small in size, easy to use and have faster response towards wide range of temperature changes from -200°C to over 2000°C. Thermocouple finds its use as control devices, measuring instruments, and to measure temperatures inside labs, jet engines, furnaces etc.

A thermocouple converts thermal energy into electrical energy. The thermocouple works by creating a voltage difference between two wires that is proportional to the temperature at the junction. This is called the Seebeck effect in honor of Thomas Seebeck, who first noticed the phenomena in 1821. It was also noticed that different metal combinations have a different voltage difference. The Seebeck coefficient is necessary to characterize the specific thermocouple being used. The Seebeck coefficient is also temperature dependent.

Thermocouple is used to convert thermal energy to electrical energy. Thermocouple working is based on Seebeck effect, which is named after the inventor, Thomas. J. Seebeck. Thermocouple has two dissimilar metals welded together at two ends (junctions). In thermocouple, Cold or reference junction is the junction that is kept at a constant or reference temperature whereas, the measuring or Hot junction is the junction whose temperature is unknown. When there is a difference between the two junction temperatures a voltage is created across the junction. This voltage is called the Electro-Motive Force (EMF) and can be calculated and subsequently used for indicating temperature. Below figure shows the thermocouple circuit setup.

In thermocouple circuit, two different metals, usually wires, are welded together to form junctions x and y, which are kept at temperatures T1 and T2. Since the temperatures at two junctions are different there is an emf induced within the circuit which is the function of temperatures between two junctions. When the temperatures at both junctions is the same, with equal and opposite electro-motive force generated at both ends then zero current flows through the junctions. In thermocouple circuit, Emf is produced between the junctions and current starts to flow between them as the temperature between two junctions are different. Emf generated in the circuit depends on the temperature of two junctions as well as the metals used in the circuit. The emf generated as well as the current can be measured using an instrument included in the thermocouple circuit. The emf or current generated provides the amount of unknown temperature so as to fulfill the usage of thermocouple as a device to measure temperature.

The emf generated in thermocouple circuit is usually very small, in millivolts range, so the instruments used for measuring emf should be highly sensitive. Two such devices for this purpose are voltage balancing potentiometer and ordinary galvanometer, among which automatically or manually balanced potentiometers are often used.

The output voltage obtained by thermocouple can be given as:

When several numbers of thermocouples are arranged in series so as to provide a substantial amount of emf output, this arrangement is called thermopile. Thermopiles being more sensitive than single thermocouple, these are used for the measurement of temperature due to radiations from stars, detection of heat produced by the living tissues and also in the place of high sensitive temperature calculating devices.

Thermocouple can be formed using different metals or alloys such as:

Two dissimilar materials used in thermocouple should satisfy certain criteria starting with the melting point of the materials, which should be higher when compared to the measuring temperature. The emf produced by dissimilar materials used in thermocouple should be large enough to accurately carry out measurements. Indirect calculation of temperature is carried out through emf being calibrated with the temperature. These materials should be resistant to the atmospheres created inside the furnaces. Thermocouple has a drawback of low output voltage and low sensitivity. Also electrical connections and non-linearity in thermocouple compared to the input-output relationship can make way to better devices for temperature measurements.

A Resistance-Temperature Detector (RTD), otherwise known as Resistance Thermometer, is a device which carries out temperature measurement related to the output resistance obtained. RTD includes a resistive material whose resistance increases and decreases proportionally with increase or decrease in the temperature. RTD is used for measurement of temperature with high accuracy, stability and repeatability in industries, laboratories etc. Metal is used as the sensing element in RTD, also, platinum metal is commonly used for making RTD called the Platinum Resistance Thermometer (PRT).

The resistance variation in a metal when compared to temperature variation is given by:

Where, Rt – Resistance at t°C, R0- Resistance at t0°C, a, b, c – constants depending on the metals used. Linear approximation of the above equation gives:

Where, R(T)- resistance at temperature T, R(T0)- resistance at temperature T0,  T= T-T0,

T= T-T0,  -- Fractional change in resistance per degree of temperature at T0.

-- Fractional change in resistance per degree of temperature at T0.

Platinum, copper and nickel are the metals that are widely used in RTD devices. Resistance variations related to temperature variations are different for these three metals, thus it is called resistance-temperature characteristics. Temperature range of platinum is 650°C, copper is 120°C and nickel is 300°C. Materials used for making RTD should be pure so that it will not deviate from conventional resistance-temperature relationship.

RTD operates as a small DC current is applied to it. As DC current flows through the resistor, impedance is provided by the resistor and resulting voltage drop is formed across the resistor. Supply current to the resistor is kept low to reduce self-heating. RTD generally find its use in bridge circuit. Configurations of RTD can be two, three or four-wire RTD configuration.

2-Wire RTD Configuration: It is used for applications that are in short distance and the process happens nearer to the controller. Here the RTD is made in contact with the Wheatstone bridge with two wires and the resulting output voltage is connected. This type is most error prone as the resistances of two wires used for connection are added directly to the resistance of RTD.

3-Wire RTD Configuration: Two-wire configuration had an error of giving out higher resistances with two wires along with RTD but here three-wire configuration reduces the effects caused due to lead resistances. Here, 2 leads are placed on the adjoining arms with lead resistances found in each arm getting cancelled out as long as the resistance in the two leads is the same. Distance that is allowed is up to 600m of cable.

4-Wire RTD Configuration: The voltage drop across RTD in 4-wire configuration consists of two potential leads and two current leads. The voltage drop occurring due to the current flow while measurement is carried is negated by the high resistance produced by two potential leads. This circuit setup is ideal when it comes to removal of lead wire resistances and its effects that were major drawback in three-wire configuration. Applications that require highly accurate and reliable measurements use four-wire configuration. Four-wire RTD configuration can handle up to 15ohm cable resistance.

RTD devices have I2R power dissipation in it causing self-heating effect. Thus RTD produces erroneous reading of the measurements. That is the supply current must be kept as low as possible to avoid self-heating.

Pressure Transducer is a type of transducer that helps in the conversion of pressure into analog electrical signal. The term pressure is defined as the force per unit area that a fluid is exerting on its surroundings. Sensing element is one of the major parts of pressure transducers. This element has constant area and the pressure transducers respond to the force applied to this area by the pressure of the fluid. The force applied deflects a bellow, diaphragm or a bourdon tube being used. Now these deflections, tensions, strains are then being converted to an analog electrical output.

The following terms must be considered while analyzing the performance of the pressure transducer. Some of the terms are:

Resolution can be defined as the smallest variation in pressure that can be detected at the transducer output. Maximum Resolution is best for pressure transducers. But due to noise in power supplies and other sources, the resolution is limited.

The measure of minimum to maximum pressure refers to the range of the pressure transducer. Generally, the transducers are selected depending upon the range.

Burst pressure is the pressure of the fluid at which failure or leakage of the pressure transducer occurs. Large amount of burst pressure can destroy the transducer.

It is defined as the maximum amount of pressure that can be applied to the transducer without causing any change in working and performance.

It is the output at which no pressure is applied to the transducer.

Variation in output for a minimum to maximum pressure range at a particular temperature.

These transducers use an elastic sensing element to sense the pressure. The major types coming under this category are C type Bourdon Tube Pressure Gauge, Diaphragm Pressure Transducers and Bellows.

Bellow is an elastic sensing element which is capable of measuring absolute pressure. Bellows are made using a copper alloy tube pressed into a corrugated shape. One end of this is sealed and the other end has a small hole. When the pressure is given through the hole, the bellows will expand at a distance, say ‘d’. This displacement is then calibrated to pressure. Also, the displacement can be amplified and can be passed to a LVDT inorder to convert it into an electrical signal.

Advantages

Disadvantages

Bourdon Tube is one of the most common types of elastic pressure sensor. They are made from brass or stainless steel. It consists of a tube made into different shapes like C, helical, spiral, twisted etc.

Usually, in a C type Bourdon Tube one end is sealed while the other end is opened. When pressure is applied to the open end of the tube, it straightens out in proportion to the pressure inside it. And when the pressure decreases, the tube returns to its normal position. All types of Bourdon Tubes are connected to a pointer.

When the pressure is applied, the pointer moves over a calibrated scale and the displacement is noted. The displacement is then calibrated to pressure. A connecting mechanism is given to speed up the movement of the pointer. We can use an LVDT in connection with the Bourdon Tube, so that the displacement produced will be converted to an electrical signal.

Electrical Pressure Transducers

Electrical Pressure transducers consist of three elements. They are:

Secondary Conversion Elements.

The types of electrical pressure transducers are: Strain Gauge Pressure Transducer, Potentiometric Pressure Transducers, Capacitive Pressure Transducers, Reluctance Pressure transducers and Piezoelectric Pressure Transducers.

It is a passive resistance type pressure transducer whose resistance changes when compressed or elaborated. The strain gauge is usually attached to a diaphragm in this transducer. Here the diaphragm is the pressure sensing element and the strain gauge is the primary conversion element. When the diaphragm moves according to the pressure applied, the strain gauge stretches or compresses. Deformation of the strain gauge varies the length, area and hence the resistance changes. Change in resistance is converted into voltage by the strain gauge bridge. This Gauge Bridge consists of one, two or four gauges connected in the form of a Wheatstone bridge. Output of the bridge will be the pressure sensed by the strain gauge.

Advantages

Disadvantages

In this type of transducer, a potentiometer is used. The potentiometer is just a variable resistance and is made by winding a resistance wire around an insulated cylinder. Wiper as a movable electrical contact slides along the cylinder touching the wire. Position of the wiper determines how much resistance is between the wire and wiper. Also, the wiper is controlled by the linkage from the Bourdon Tube and the pressure is determined from the resistance of the potentiometer. Figure below shows the diagram of the potentiometric pressure transducer. Here the Bourdon Tube acts as the sensing element. When the pressure increases, the Bourdon Tube gets straighten out and this motion causes the linkage to move the wiper across the potentiometer. As the wiper moves, the resistance increases and this is equivalent to the pressure sensed by the Bourdon Tube. Resistance change is then converted to current or voltage.

Advantages

Disadvantages

This type of transducer consists of a movable and fixed plate. Here the diaphragm is used as the movable plate. The fixed plate is placed near to the diaphragm and they together act as the two plates of a parallel plate capacitor and satisfies the equation given below,

The diaphragm expands and contracts when the pressure being applied changes. Due to change in pressure, the movable plate will move and the distance ‘d’ changes. When the pressure increases, distance decreases and the capacitance increases. The opposite happens when the pressure is decreased. Obtained change in capacitance is calibrated to measure the change in pressure. A bridge circuit is used to convert the change to a voltage output.

Advantages

Disadvantages

Reluctance pressure transducers are basically classified into two types. They are LVDT and Servo Pressure Transducers.

Commonly known by the name Force Balance Pressure Transducer. As a transducer, it produces an electrical signal proportional to pressure. Figure below shows a servo pressure transducer. When the pressure p1 becomes greater than p2, the diaphragm moves and causes the movement of the force beam. Due to this the long end of the force beam moves the magnetic material to the reluctive detector. Signal from the reluctive detector is then converted from ac to dc. This dc signal is then sent to the amplifier. The amplifier responds by activating an induction motor that moves the force beam to its orginal position.

These pressure transducers depend upon the principle of piezoelectricity. When the pressure is applied to the piezoelectric materials, an electric charge will be generated. The piezoelectric pressure transducer consists of a diaphragm, a piezoelectric crystal and amplifiers. At first, the diaphragm will transmit the pressure sensed to the piezoelectric crystal Y1. According to the principle, Y1 will produce an electric charge which is then amplified by the charge amplifier. Here the compensation crystal Y2 is used to avoid the fast acceleration of the transducer that creates more pressure on Y1. Now, the signals from Y2 are amplified by the difference amplifier which subtracts and gives out the pressure only.

Advantages

Disadvantages

Industrial applications require the use of pressure transducers mainly. Pump monitoring, compressor control, process automation and control, construction machinery, HVAC and refrigeration, hydraulic and pneumatic sensing are some areas where pressure transducers are used. Last but not the least there are many pressure measuring instruments like Barometer, Manometer etc. apart from the diaphragm, bellows and bourdon tubes which are not commonly used because of its disadvantages.

LVDT is referred to Linear Variable Differential Transformer is an electromechanical transducer/transformer used to convert linear displacement into corresponding electrical signal having amplitude and phase information. LVDTs are linear position transducers that are frictionless inherently, robust about life cycle, low hysteresis and known for its excellent repeatability. LVDTs operated with AC sources can be used at temperatures that are cryogenic or up to 1200°F in environments that are harsh and which is prone to higher shock levels and vibrations. LVDTs are used for measuring movements that ranges from a few millionth of an inch to inches in length. Nuclear reactors, hydraulics, satellites, power turbines etc. are the places where LVDTs are used. LVDT operation depends on electromagnetic coupling and need not require a contact, which is electrical in nature, between the coil assembly and the moving part.

The LVDT consists of a non-ferromagnetic hollow cylindrical form or bore which is wounded by a primary winding at its center and two secondary windings on the either side of the primary winding. The secondary wings are such that they have equal number of turns with same length spaced equally from primary winding, so that the null position and linearity is not affected and are wound in opposite directions, so that the cumulative output voltage is the difference between the voltages in the secondary coils. S1 and S2 denote two secondary coils. A ferromagnetic tubular iron core is placed inside the cylindrical form which moves to and fro, axially within the hollow cylindrical form. This core is mechanically coupled to the shaft with a thread handle whose positional change is to be determined. The core has no physical contacts with the coils and its width is good enough to have the radial clearance between the cylindrical form and core. A shielding is given to the cylindrical structure to protect the winding and contains the magnetic field surrounded with the coil for sensing. Primary excitation is given to the primary winding by an alternating current of desired frequency and amplitude. The electrical output obtained from the two secondary coils is a differential AC voltage which varies according to the positional change occurring to the core within the cylindrical form.

Primary coil gets excited from an alternating current source and thereby voltages get induced in the secondary coils. The ferromagnetic core inside the cylindrical form enables a magnetic flux path that links the primary as well as the secondary coils. The secondary are opposite in nature providing output voltages that are equal and in opposite polarity which gives a resultant zero output voltage. The null position is when the core lies below the primary winding making the differential output phase angle to 90 degrees.

When the core is moved from null position there is an electromagnetic imbalance which generates different output voltage in the secondary coils. This differential AC voltage is directly proportional to the magnitude and direction of linear displacement of the core. When the core is moved to the secondary coil S1, then the voltage induced in secondary S1 is greater than that induced in S2 giving a net voltage as ES1- ES2. When the core is moved towards the secondary S2, voltage induced in S2 is much greater than that induced in S1 giving net voltage as ES2-ES1.

Sections